Firewalls are fire-resistant barriers that reduce the potential for fires to spread. The International Building Code (IBC) defines a firewall as a fire-resistant wall with protected openings that extend continuously from the foundation to or through the roof to help aid in fire suppression. Additionally, fire walls have significant structural stability that makes it difficult for it to collapse under intense conditions.

Fire walls differ from conventional fire separations in many aspects. A fire separation functions as a barrier to protect against the spread of a fire but can be easily removed if the surrounding structures begin to collapse. It acts as a shield against radiation and fire penetration and protects occupants from the immediate effects of fire. Typically, there is an evacuation or intervention by the fire service before any building collapse occurs. Firewalls remain in place to prevent fire from spreading into surrounding spaces and also to prevent a building from collapsing without immediate intervention from a fire service. A continuous fire separation is typically required in residential construction, which is made of fire resisting walls, floors, doors, ducts, etc.

Fire resistance refers to the prevention or delay of the passage of excessive heat, hot gases, or flames under fire conditions. Precast concrete components can be designed to meet any degree of fire resistance required by building codes or authorities. The PCI Design Book indicates that the fire resisting rating of building assemblies can be determined from ASTM E119 standard fire tests, code-approved empirical data, or by calculation procedures outlined in PCI Section 10.3.

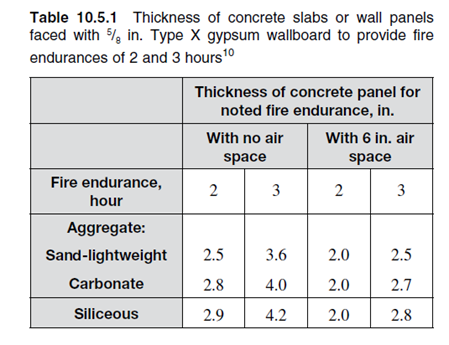

PCI Section 10.5.1 indicates that for concrete slabs or wall panels, the temperature rise of the unexposed surface depends mainly on the thickness and aggregate type of the concrete. Additional factors include density, moisture condition, air content, and maximum aggregate size. Within the usual ranges, water-cementitious ratio, strength, and age have an insignificant effect.

PCI Section 10.5.1 indicates that for concrete slabs or wall panels, the temperature rise of the unexposed surface depends mainly on the thickness and aggregate type of the concrete. Additional factors include density, moisture condition, air content, and maximum aggregate size. Within the usual ranges, water-cementitious ratio, strength, and age have an insignificant effect.

PCI figure 10.5.1 also shows the fire endurance (heat transmission) of concrete slabs as influenced by aggregate types and thickness. The curves represent air-entrained concrete made with air-dry aggregates that have a nominal maximum size of ¾” and fire tested when the concrete was at the standard moisture condition (75% relative humidity [RH] at mid-depth). On the graph below, concrete aggregates are designed as lightweight, sand light weight, carbonate, or siliceous. Lightweight aggregates include expanded clay, shale, and slate, which produce concretes having densities of about 95 pcf to 105 pcf without normal weight sand replacement. Lightweight concretes, in which normal weight sand is used as part of all of the fine aggregate and the weight does not exceed 120pcf, are designated as sand-lightweight. Carbonate aggregates include limestone and dolomite, which consist primarily of calcium and/or magnesium carbonate. Siliceous aggregates include quartzite, granite, basalt, and other hard rocks.

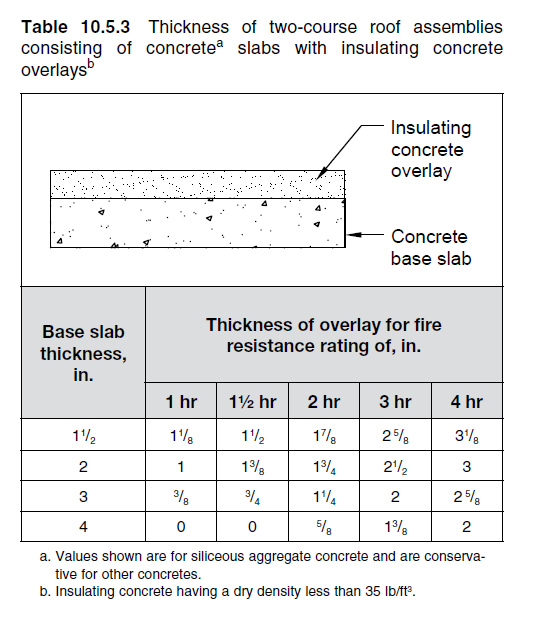

The following Tables are provided PCI for typical fire resistance rating of assemblies.

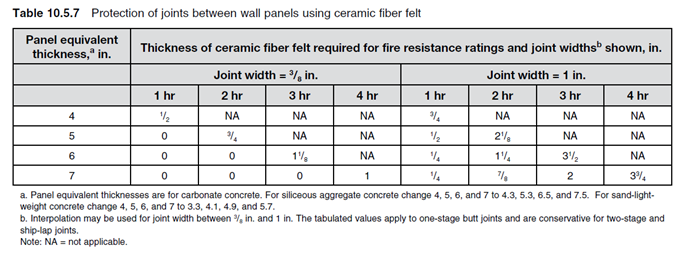

PCI Section 10.5.6 discusses the treatment of joints between wall panels. When required by code, joints between wall panels should be detailed so that the passage of flames or hot gases are prevented and that the transmission of heat does not exceed the limits specified in ASTM E119. Concrete wall panels expand when heated, so the joints tend to close during fire exposure. Non-combustible materials that are flexible, such as ceramic fiber blankets, provide thermal, flame, and smoke barriers, and when used in conjunction with caulking materials, can provide the necessary weather-tightness while permitting normal volume-change movements. Joints that do not move can be filled with mortar. Refer to PCI MNL-124-89 for more information.

PCI Section 10.5.6 discusses the treatment of joints between wall panels. When required by code, joints between wall panels should be detailed so that the passage of flames or hot gases are prevented and that the transmission of heat does not exceed the limits specified in ASTM E119. Concrete wall panels expand when heated, so the joints tend to close during fire exposure. Non-combustible materials that are flexible, such as ceramic fiber blankets, provide thermal, flame, and smoke barriers, and when used in conjunction with caulking materials, can provide the necessary weather-tightness while permitting normal volume-change movements. Joints that do not move can be filled with mortar. Refer to PCI MNL-124-89 for more information.

The IBC addresses joints in exterior walls in various sections of the code:

1. In Section 713, joints are specified to have the same fire-resistance rating as the wall. Walls that are permitted to have unprotected openings are noted as an exception to this requirement.

2. Table 704.8 is used to determine if unprotected openings are allowed as well as designating the percentage of unprotected openings allowed.

3. Section 704.13 also addresses joints and has the same exception as Section 713.

4. Section 721.2.1.3 addresses joints in precast concrete walls. This section requires that unprotected joints be included as openings in the calculation of opening percentages for comparison to the allowed opening percentage of Table 704.8.

Fire resistance required for the wall shall be provided at the joints when no openings are permitted. PCI Table 10.5.7 shown below is based on the results of fire tests of panels with butt joints. The tabulated values apply to one-stage butt joints and are conservative for two-stage and ship-lap joints.

PCI indicates that joints between adjacent precast concrete floor or roof components may be ignored in calculating the slab thickness, provided that a concrete topping at least 1.5” thick is used. Where no concrete topping is provided, joints should be grouted to a depth of at lease one-third the slab thickness at the joint, or the joints made fire resistance in a manner acceptable to the authority having jurisdiction. No joint treatment is required in pretopped, double-tee parking structures when classified by code as open parking structures.

PCI Section 10.9, shown in the figure below, provides guidelines for the protection of connections. Connections such as the bearing between precast concrete panels and the concrete footings or beams that support them do not generally require special fire protection. If the panels rest on elastomeric bearing pads or other combustible materials, protection of the pads if not generally needed because deterioration of the pads will not cause collapse. Connections that can be weakened by fire and jeopardize the structure’s load-carrying capacity should be protected to the same degree as that required for the supporting components. For example, an exposed steel bracket supporting a panel or spandrel beam will be weakened by fire and might fail causing the panel or beam to collapse. Such a bracket should be protected. The amount of protection depends on the stress-strength ratio in the steel at the time of the fire and the intensity and duration of fire. The thickness of protection materials required in greater as the stress level and fire severity increase.

PCI Figure 10.9.1 shows the thickness of various fire-protection materials required for fire endurances up to 4 hours. The values shown are based on a critical steel temperature of 1000 ˚F, that is, a stress-strength ratio (fs/fy) of about 65%. Values in Fig. 10.9.1(b) are applicable to concrete or dry-pack mortar encasement of structural steel shapes used as brackets or lintels.

For additional information on precast fire walls and fire resistance, please contact Daryl Burns, PE at dburns@delta-eas.com.